Rich industry experience

Research and developmentproduction of supercharger, micro cylinder, cutter module, quick joint and other productsWe provide professional equipment and services for the automatic solution of heat heating in mold

The 5 core advantages of in-mold fervent

Rich industry experience

Research and developmentproduction of supercharger, micro cylinder, cutter module, quick joint and other productsWe provide professional equipment and services for the automatic solution of heat heating in mold

Professional technology

Successfully applied formore than ten patents,with independent intellectual property rightsHave continuous research and development ability and focus on the application and promotion of in-mold heating technology

One-stop service

Focus on the research and development, production of related products, sales and serviceProducts are widely used in automotive, precision electronics and other industries

Strict quality control

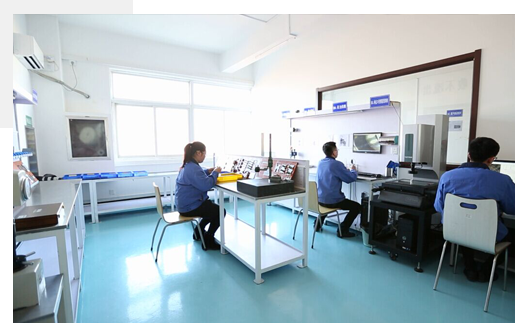

Our company carries out strict management and testing of product moldsExcellence, quality assurance

Perfect after-sales

To provide you with 7*24h after-sales, pre-sales consulting services and to think about what you think as the standard of doing things Professional, ability, value is our constant pursuit

ABOUT US

Haidelike is committed to the research and development, production, and integration of sales and service of hot cutting automation products in molding molds, providing customers with supporting equipment and services for hot cutting automation solutions in mol...

MORE

Quality management

Molding mold in the mold eager to develop production

Service hotline:0535-6108768

NEWS

12-09Do you know what kind of technology is in-model heat?

Usually after injection molding, the head and the product are connected through a gate. The workers need to trim the gate. The labor intensity is high and the c···

MORE12-09Share key technologies for in-die cutting applications

In-die cutting technology is an injection molding technology, which is widely used in Europe and the United States. More than 50% of the molds produced by many ···

MORE12-09What factors affect the compression speed of the die cutting equipment?

The compression speed of the in-die cutting equipment is affected by the following factors:Pressurization mode, input flow of low pressure system, model size of···

MORE12-09How to choose in-mold laser cutting to assist parts in stamping dies?

1. Pay attention to the total number and layout of the die on the grinding tool. Because the number of mold cavities and the arrangement of layout methods have ···

MORE12-09What is the in-mold heat technology of injection parts?

In-mold heating is an automatic mold injection molding process that cuts or breaks the gate before the plastic mold is opened, so as to realize the separation o···

MORE12-09Do you know what kind of technology is in-model heat?

Usually after injection molding, the head and the product are connected through a gate. The workers need to trim the gate. The labor intensity is high and the c···

MORE